|

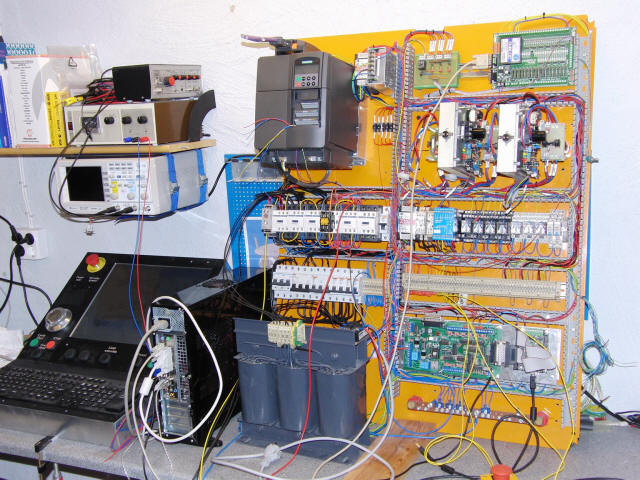

Quite early in the process

I stripped out everything in the original

electrical cabinet and

removed the mounting panel to make it easier to mount

all the new stuff. Circuit brakers, contactors, relays,

resistors, servodrives, spindle drive, break-out-board

etc etc.

Pretty basic stuff here

so far. Fuses for the various powersupplies, VFD, and

computer. Contactors and power resistors for the

softstart circuit of the main transformer and inrush

limiter for the main filer capacitors. Two of the three

remaining resisotrs are for the powerdump circuit and

the third is a bleeder that quickly discharges the

powersupply capacitors.

A 24VDC powersupply for

the control voltage, a proper E-stop relay (the blue box

in the middle) and a row of terminals for

interconnections.

The main powersupply

transformer3-phase rectifier and filter capacitors with

the powerdump circuit on top. Basically I'm just testing

the softstart and E-stop circuits.

Here you

can see that I've removed the VSD-A drives and installed

(2 out of three) HP-UHU drives instead, the VFD for

the spindledrive have been mounted, break-out-board,

CUBLOC PLC for the control-panel and various other

things. You can also get a glimse of the control panel I

designed for this project.

The HP-UHU servo drive

have a combined fault input/output. If the fault I/O on

all the drives are connected together they will all

stop if any one faults. This is nice and all but the

problem is you have no way of knowing which one that

caused the fault in the first place. So I designed a

circuit that with the help of the CUBLOC PLC and some

ladder logic latches the fault state of the offending

drive and then stops the others. The CUBLOC is connected

to Mach3 via MODBUS so I can make Mach3 show me which

drive it was that caused the fault.

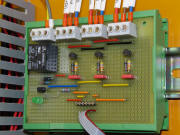

Here's a closeup of

another little board I made, or two actually. The HP-UHU

needs 15VDC for its low voltage circuits. I already had

24V and 5V powersupplies in the system and I couldn't

really find an affordable 15V switchmode supply for

DIN-rail mounting so I made a couple of PCB's with a

7815 regulator and some filtercaps. 24VDC in, 15VDC out

- works fine.

The lower one of the

two PCB is a filter for the motor power supply. The

wires between the power supply and the drives are quite

long so I wanted to put an extra filter cap as close to

the drive as I could to help the internal cap share the

ripple current. The PCB also houses a fuse with an

antiparallell diode and a MOV. The diode lets current go

from the drive to the powersupply in case the fuse blows

and the MOV together with the capacitor hopefully clamps

the voltage spike that develops when the fuse blows,

protecting the drive. I haven't had a single fuse blow

on me yet so it's still unkown if it works.

These two photos shows

pretty much the same thing. The one on the left side is

the one of the last ones I took before the panel went

back into the cabinet on the machine. I had it like that

for quite some time during testing and developement of

the control panel, PLC code etc. The right hand photo

shoes the panel mounted inside the cabinet. I installed

a fluorecent light in the top of the cabinet to make it

easier to work with it. Next step was to install the

transformer, rectifer and filter capacitors for the

motor power supply. They'll be mounted pretty much as

they are in the left photo.

Here are two closeups.

To the left, the filtercaps and powerdumps circuit with

the transformer in the background. You can see the

three-phase rectifier mounted to the panel. I think and

hope that the panel will provide enough cooling for the

rectifier, I'll have to keep an eye on that once I start

running the machine.

The right hand photo

shows the three servo-drives. Encoder cables coming in

at the bottom, power coming at the "front" and

motorcables going out at the top. I've mounted thermal

switches to the heatsinks, wired in the E-stop chain so

it shuts down the machine in case the heatsink

temperature goes above 60°C. The same type of switches

are mounted on the heatsink for the power resitsors and

the servo-motors have internal thermal switches. They

are all wired to separate relays and the relays are then

wired to the E-stop chain as well as to the CUBLOC PLC,

that way I can let the PLC tell Mach3 what caused the

E-stop in case it happens. Servodrive overheat,

servomotor overheat, resistorbank overheat etc.

My intention is to run

this machine with a

Smoothstepper from Greg at Warp9Tech Design. This

looked like a very promising motion controller when it

was introduced but now, well after year the plugin is

still in beta and things that was promised looong ago

still doesn't work. So far thoguh it have been working

quite good during general testing and sisnce the machine

isn't really finished yet I'll just have to see what

happens. Anyway, initially I had the Smoothstepper

mounted next to the break-out-board but that din't work

very good. Every time I hit E-stop and the contactor

switched in bleeder resistor across the powersupply the

Smoothstepper locked up and lost the USB connection to

Mach3. So I decided to move it into the computer case

instead. The computer, by the way, will be mounted to

the inside of the cabinet door. The computercase is a

low profile type case and I couldn't find any low

profile mounting brackets for the 25-pin female

D-connectors for the Smoothsteppers so I decided to make

some cutouts in the "blank" ones that came with the case:

This move provided a

nice shielded place for the somewhat sensitive

Smoothstepper. I cut off a USB-cable and slodered a new

female header to it making it short and nice, right from

the USB-header on the motherboard to Smoothstepper.

More later.....

2009-09-30 |