|

Initially, when I thought I was going to use the VSD-A from Granite Devices, I

fabricated some brackets and extensionshafts so I could

mount some really nice SCANCON encoders I had to the

motors. These encoder have differential linedriver and

3600 lines resolution, 14400 counts per revolution in

quadrature - perfect for the VSD-A.

This worked very nice

with the VSD-A but because of the limited acceleration I

switched to the HP-UHU drive which I found, during

testing, had a max encoder count frequency of ~130kHz.

With 14400 counts rev that would have allowed me a

maximum speed of 541rpm, or rougly 1/4 of the motors

rated speed - not very good.

I decided to get new

encoders, I settled for the USDigital E7P because of

three main reasons. The E7P is available with

differential output, it's small enough to fit inside the

already fabricated covers and it was availble with 625

lines of resolution which would give me a nice round

figure of 1000 steps/mm on the X- and Y-axis, 2000

steps/mm on the Z-axis and stay well below the 130kHz

frequency limit on the HP-UHU. (2000rpm * 2500 / 60 =

83.3kHz). Can't go wrong with that can you?

Well, to make a very

long story a whole lot shorter the USDigital E7P encoder

simply refused to work reliably with my setup. The UHU

servo chip has an internal counter that keeps track of

any invalid transistions on the encoder input. For

example the the state of the A- and B inputs can't go

from 0 0 to 1 1 with out "going thru" either 1 0 or 0 1.

If that happens it means that we longer know for sure

where the motor is. This can happen for a few reasons.

The frequency (ie the motorspeed) is to high so the chip

can't keep up or it could be noise coming into the

system causing false readings. I knew it wasn't a speed

issue because I had verified the max frequency when

testing with the SCANCON encoders. Besides it didn't

matter one bit if I tested at 1000rpm or 10rpm it still

lost position. So it had to be a noise problem then.

During the course of

several weeks I tried every trick in the book, and some

that are not in the book to get these encoders to work.

I tried with long and short cables, twisted and

untwisted pairs, shielded and unshielded, many different

grounding strategies regarding the shields and the

common point for the motor power supply and the low

voltage supply of the drive. I tried with different

voltages for the motorpowersupply, anything from 130VDC

down to 40VDC.

I tried feeding the

encoder from a battery powered supply, I tried bypassing

the differential receiver in the drive, using only the

A- and B-singals (not the complementary ones). I tried

with a homebrew linedriver circuit, I switched motors

and I switched drives - no matter what I did I got the

same results. Drive complains about invalid transitions

on the encoder inputs with loss of position as result -

unacceptable.

Being pretty

confident it was a problem with the actual encoders I

tried two other encoders I had around. One Hengstler and

one AMT102, both worked beautifully although the

Hengstler had 3600 lines so the speed had to be held

down. I tried a few of the different grounding and

shielding strategies I had tried with the E7P and it all

worked, even with unshielded cable. Yet nothing worked

with USDigital E7P encoders.

During all this

USDigital claimed that there had to be something wrong

with my setup since I could verify the integrity of

signals on the E7P with my scope - which I could. Rise

and falltimes looked OK, voltage levels OK, dutycycle

and phaseshift OK but never the less - when mounted on

the motor it simply DID NOT WORK.

After telling them that

my system worked with 2 other encoders but not with the

E7P they offered to take them back "for investigation"

but I had to pay for the shipping. At this point I was

so tired of it I decided to write it off as a lesson

learned:

Never

ever buy USDigital crap again.

But now what, I still

needed enocders. I got pointed towards Renco Encoders

and found their R35i model. After E-mailing them it

turned out it was available with differential linedriver,

625 lines and it would fit inside the already fabricated covers.

After explaining I about my problems with 'another

manufacturers' encoders they assured me I would have no

such problems - guess what, they where right! The Renco

35i, the AMT103 the Hengstler AND the SCANCON all works

just

fine while the USDigital E7P doesn't. (Yes, I DID try more

than one E7P with the same results.)

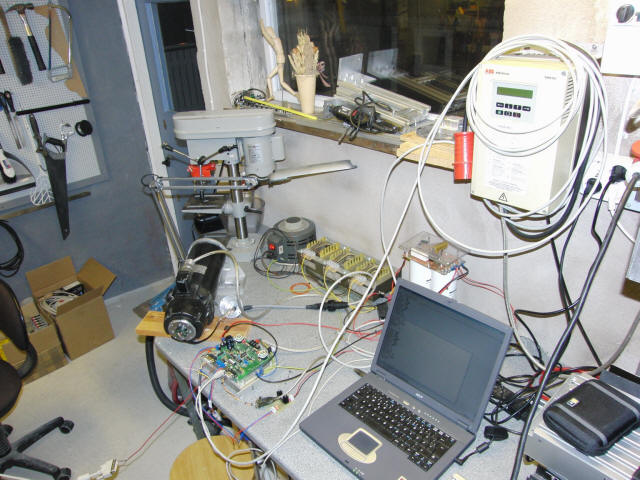

The next photo shows

the final test setup with the Renco R35i encoder. The

encoder cable during this test was roughly 15m long, twisted pairs

and

as a test the shield/screen is left floating. The cable

was also wrapped around the running VFD you see on the

wall there. It was left like this, cycling thru a G-code

program for hours without any sign of trouble.

|