|

As you probably can see in

one of the first photos the mounting brackets for the servomotors

as well as the pulleys had seen better days. I'm sure

they would've worked but I just couldn't stand the way

they looked so I decided to make new ones.

I started by looking up

the various belts and pullies available. Originally the

machine was equipped with T10 belts but I settled for AT5

instead. The AT-profile is supposed to be a little

better than the T-profile when it comes to positioning

applications and although it can't transfer just as much

torque per tooth as the T-profile there will be more

teeth in contact with the pulley so I'm pretty sure it

will suffice.

I wanted a 2:1 ratio

between the motor and screw so I went for 30 teeth on

the motor and 60 on the screws. The Z-axis is a little

special, it has a 90 deg bevel gear with a 2:1 ratio but

fitting the 60 teeth pulley to the gear-shaft won't work

because it would interfere with the Y-axis sadle of the machine. So for the

Z-axis there's first a 2:1 belt-transmission, then

there's a 1:1 belt and then there's the 90 deg 2:1 gear

reduction for a total reduction of 4:1.

Here's a screenshot of the

CAD drawing for the three axes. (Sorry for the Swedish

notations in the drawing...)

With the CAD done it was

just a matter of ordering the belts, pulleys and

mounting hardware. The original pulleys were fitted with

a key but I don't have access to tooling for that so I

went for the type that clamps to the motor-shaft.

Besides, I've had bad experience with using keys in

applications like this where the axis of rotation changes direction

on a regular basis. If it's not absolutely 100% tight it

will develop a lash and once that happens i going

downhill, fast.

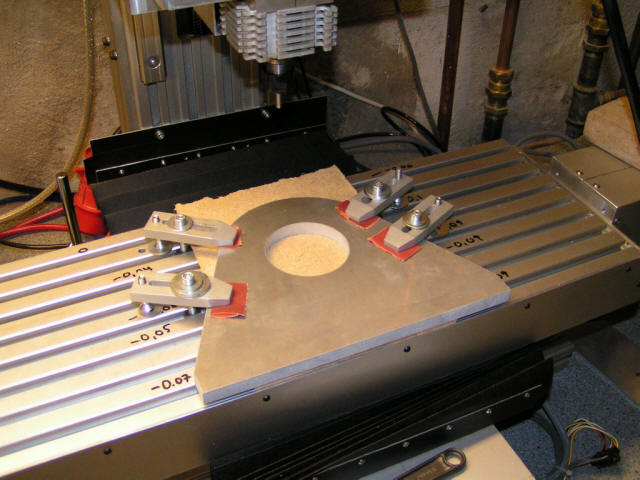

For the X- and Y-axis I

got some 12mm aluminum sheet watercut at a local shop. I

then mounted them on my small

machine in order to bore out the hole for the boss

on the servo-motor as well as drill and countersink the

holes for mounting the motor.

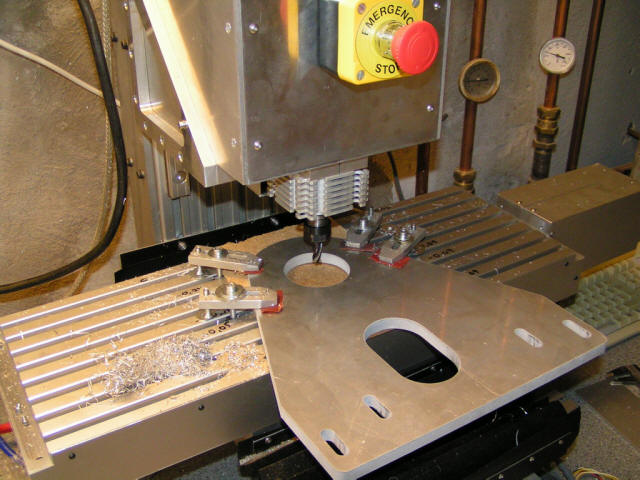

I generated a helical

toolpath and let the machine bore out the hole to final

dimension.

It turned out pretty good...

And here's the more or

less finished motor-mount for the Y-axis. The two

remaining holes are for dovel pins that will be fitted

once I know it all works out as it's supposed to.

For the X-axis I went

about the same way. Unfortunately I made a mistake while

measuring the bearing-plate on the machine to which the

motor mount will be mounted so I ended up with an extra

slot in the wrong place. It doesn't matter much but even

so I hate it when that happens.

This is the "original" but

it turned out that the four small slots shouldn't be

evenly spaced as I had drawn them...oh well.

<Back>

<Next>

|