|

Well, with

the machine almost ready I thought: Hey, I need another project, why not build a control panel for it.

Besides I didn't fancy the idea of fiddling with the

mouse and keyboard with metal chips flying all over the

place. In retrospect it seems I can't let go of the mouse even though

I have this panel, but that's another story.

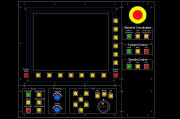

The

idea was to use a 15" LCD-screen and mount buttons

around the perimeter of the screen and then, by using

Mach3's screen designer software I could place labels on

the screen indicating what that particular button did at

that particular moment. (Known as Soft buttons or

Soft-keys). The

idea was to use a 15" LCD-screen and mount buttons

around the perimeter of the screen and then, by using

Mach3's screen designer software I could place labels on

the screen indicating what that particular button did at

that particular moment. (Known as Soft buttons or

Soft-keys).

I started by disassembling

the 15" monitor I had and took some measurements on it.

Next I sketched up the design in AutoCad. The

controlpanel

consists of a three separate panels mounted on a frame

of 20mm square aluminium tubing. A lot of thought went

into what functions I should have on the panel. I did,

for example, include buttons for coolant even though my

machine doesn't have it. (yet...)

When the designwork was

done and the three panels where cut to size I used the

engraving machine we have at the place I work to cut the

holes for the buttons and engrave the legends. The

following three pictures shows the progress on one of the

three panels. First cutting and engraving, then a

cleaned up panel and last the finished panel ready to

install the buttons and rotary encoders.

And

here's the finished panel with buttons, encoders and

knobs installed. The big knob to right was supposed to

used as an MPG but I later bought a real MPG and "retrofitted"

the panel with one. And

here's the finished panel with buttons, encoders and

knobs installed. The big knob to right was supposed to

used as an MPG but I later bought a real MPG and "retrofitted"

the panel with one.

The next three pictures shows the panel for the

LCD-screen being engraved and then the opening for the

screen is cut out on a little bigger machine.

And here it is, first with the buttons installed and

then with the LCD-screen mounted and finally a view of

the finished panel.

The buttons are connected to a X-keys matrixboard which

in turn is connected to the PC thru the USB-port. The

X-key software lets you program each button to send one

or more key-strokes to the PC when the button is pushed.

This lets you tie whatever function you may like to the

different buttons. The buttons below the screen for

example sends the equivalent of pressing ALT+1 to ALT+7

on the keyboard. This makes them switch between the

different screens in Mach3. The buttons on the side

sends ALT+F1 to ALT+F6 and by putting buttons on the

screen along the side and setting it's hotkey property to corespond with the pushputton we have a softkey.

The key, pun intended, here is that ALT+F1 can be used for different

functions on different screens inside Mach3.

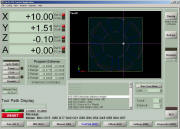

Here's two screenshots

from Mach3. The buttons below and on the side lines up

with the pushbuttons on the panel. Nice...

And here's a shot of the

internals of the finished control panel. Clearly visible

is the LCD-screen. In the upper left corner is the

E-stop switch and in the lower left is Nemicon MPG

encoder.

On the right side we have

the X-keys board and above that a little interface board

with a PIC microcontroller. This boards purpose is to

read the two rotary encoders (ALPS EC11B-20202)

used for feedrate override and spindle speed override

and convert the signals to 'key presses' that the X-keys

board then sends to PC.

The last photo shows the

completed panel up and running Mach3 with my custom

screenset. You can see that the original MPG now is replaced

with the NEMICON.

<BACK>

<NEXT>

|