|

I got hold of some rather

nice heavy duty aluminum extrusion that measures 90 X 180 mm and had a

fairly large center cavity that I thought would be

perfect to run the ballscrew in. All I needed to do was

to open up the top section of the extrusion thus

creating sort of a tunnel for the screw to run in. It

also had two circular cavities to use for fixing

the ballscrew bearingblocks.

This

is actually the first picture I took while building it.

As you can see it have come quit a way already. I wish

I'd taken more photos along away the way but I was

occupied building the thing.... This

is actually the first picture I took while building it.

As you can see it have come quit a way already. I wish

I'd taken more photos along away the way but I was

occupied building the thing....

In this photo the X-axis and Y-axis

are nearly finished and work are about to start on

the Z-axis column. You can clearly see ballscrew running

in the "tunnel" of the extrusion on the Y-axis and on

the top of the Z-axis column you can see the profile of

the extrusion.

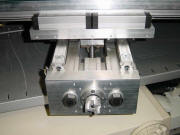

Here's a closeup of the "business-end" of the Y-axis

linear ways and ballscrew as well as the "sadle" and the

X-axis linear bearingblocks. The ballscrew (from

Isel) is hold firmly in place by two angular

contact bearings inside the aluminiumblock. The outer

races of the bearings are mounted with a spacer between

them and held in place by the flange. The inner races

are then preloaded against each other by tightening the

nut on the ballscrew (not visible in this photo). This

effectivly holds this end of the ballscrew in place. At

the time I hadn't decided what motors to use so the

block where drilled and tapped for both NEMA 23 and

NEMA34 motors.

Two aluminium plates of the same dimensions where fly

cut to make them flat. One was then drilled to be

mounted on the Y-axis bearingblocks and the other to be

mounted on the X-axis bearingblocks. The Y-axis plate (bottom

one) have slightly oversized holes lined up with

threaded holes in the X-axis plate and the plates are

fixed

together with screws. This allows the axies to be

adjusted slightly so that they are perpendicular to each other.

At the bottom of this picture you can see the base of

the machine, the Y-axis linear ways and bearningblocks.

Then there's the two aluminium plates, the X-axis linear blocks and it's linear ways which is screwed to

underside of the table. Running down the center of the

table is the X-axis ballscrew with it's ballnut far in

there, between the bearingblocks.

At first I intended to use one linear block per rail for

the X-axis but ended up using two. That lost me roughly

130mm of travel on that axis but it gained so much

rigidity that i decided it was worth it.

This photo shows the driven end of the Y-axis ballscrew.

A piece of 50 X 50 mm aluminium bar holds the angular

contact bearings for the screw. The bearing block is

then mounted to the table by the six M5 screws. The two

milled out sections on each side of the block is for

clearence for the linear bearings lubepoints when the

table is at it extreme end of travel.

Here's

another view of the same piece. You can see flange

holding the angular contact bearings in place, the shaft

coupler and the mounting plate for the stepper motor.

Also visible is the T-slots on the table. The small

holes on the side, just below the table were intended

for screws to further fix the block in position to

the table but it turned out not needed in the end. Here's

another view of the same piece. You can see flange

holding the angular contact bearings in place, the shaft

coupler and the mounting plate for the stepper motor.

Also visible is the T-slots on the table. The small

holes on the side, just below the table were intended

for screws to further fix the block in position to

the table but it turned out not needed in the end.

This

is an overview of the base, X and Y axis and table. With

a CD cover for size comparation. This

is an overview of the base, X and Y axis and table. With

a CD cover for size comparation.

The

Z-axis is constructed in the same way as the Y-axis.

Except that the lower end of the ballscrew is hold in a

bearingblock which is just tightly pressed into the

cavity of the aluminium extrusion. The

Z-axis is constructed in the same way as the Y-axis.

Except that the lower end of the ballscrew is hold in a

bearingblock which is just tightly pressed into the

cavity of the aluminium extrusion.

This picture shows the Z-axis viewed from the top down.

You can see the linear rails and blocks, the ballscrew

and nut and the spacerblock that attaches the nut to the

actual Z-axis.

Here's

an overview of the machine as it looked when the

initial testing begun. The spindle in the picture is a

Bosch 600W router but it has since been replaced by an

ER16 collet spindle and 3-phase motor with VFD-control.

In the lower left corner you can see part of the

electronics cabinet and if you look closely you can see

the three wonderfull G210's. You can find out more about

the electronics here. Here's

an overview of the machine as it looked when the

initial testing begun. The spindle in the picture is a

Bosch 600W router but it has since been replaced by an

ER16 collet spindle and 3-phase motor with VFD-control.

In the lower left corner you can see part of the

electronics cabinet and if you look closely you can see

the three wonderfull G210's. You can find out more about

the electronics here.

<BACK>

<NEXT>

|