|

To be able to make the

robot balance I realised I needed some sort of control

algorithm and I decided that a PID regulator probably

would provide the the largest chance of success.

To

develop and test the code for the PID regulator I used

the same approach as the nBot's creator with a pole

pivoting on top of the robot. A potentiometer

measures the angle of the pole and sends that value the

PIC's onboard A/D converter. The A/D converter sends the

value to the PID regulator whose job is to calculate how

to drive the motors so that the pole remains upright.

A PID regulator is

basicly three regulators running in parallel, each

acting on the Error

signal, in other words the difference between the

desired value and the actual value. Each regulator, or

term, has it's

own gain, that way you can adjust how the regulator

responds to various situations.

-

The P-term

is the proportional term. The larger the error is

the more it will contribute to final output of the

regulator.

-

The I-term

is basicly the sum of all errors in the past. That

is, the longer there's an error present at the input

the more will the I-term contribute to regulators

total output.

-

The D-term

is the derivative or difference between the current

error and last error. This can respond quickly to

sudden changes in the error signal and as well as

having a damping effect on the total output when the

actual value is getting closer to the desired.

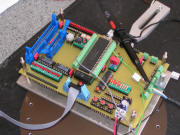

Here's two photos of

the testbed. The first shows the overall mechanical

platform. The motor driver IC's are mounted on a

solderless breadboard on the lower deck and the pivot

joint for the inverted pendulum is mounted on the second

deck.

There's two support

'struts' acting as casters that prevents the robot from

tipping in any direction. For this test setup the signal

from the potentiomter as well as power and PWM signals

to the motor drivers were fed to the CPU via cable so that I didn't

need to worry about battery voltage or my PIC development

board suddenly taking off, heading for the wall.

Here's a shot of the

PIC development board. The black cable coming in from

the lower right corner is the power to and signal from the potentiometer

and the grey and green ones are the PWM and direction

signals to the motor drivers. This board will eventually

be replaced with one dedicated to the robot.

After quite a few hours (days

actually) of coding and trial and error I finally

managed to get the robot to balance the pole (well

almost). Here's a couple of low-res videos of the

balancing act.

After I got the robot to

balance the pole I was eager to make it balance itself.

<BACK>

<NEXT>

|