|

With the housing done I

decided to tackle what was coming to be the most

problematic part of the whole project. When I'm

writing this I still don't know if it will work or not.

I decided that I wanted

the spindle shaft hardened and ground, at least the

lower part with the taper and after discussing it with a

local company they supplied me with a piece of SS2511

round bar.

Unfortunatly I didn't snap

any photos while machining the shaft but here's two I

took fresh off the lathe:

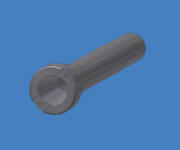

The main diameter of the

shaft is 30mm and it is 240mm long. There's a M32X1.5

thread that will be used to lock the bearings in place.

This photo shows the setup

I did to machine the slots and mounting holes for the

drivedogs. First I made a collet kind-if-thing that fits

the 30mm OD of the shaft. Then I used two Vee-blocks in

the vice to clamp it.

Using a 10mm endmill I

then machined the slots.

And here's the finished

shaft before sending it out for hardening and grinding.

You can see the "collet" I mentioned just above the

threaded part of the shaft.

So now comes the problem.

The company that does the hardening and grinding for me

told me to leave 0.4mm on the surfaces I wanted them to

grind - and I did. But since I shouldn't harden OR grind

the upper part of the shaft I machined that to it's

final dimension. (30mm). This didn't turn out well

because the shaft got oval from the heat of the

hardening and now there wasn not enough material to

machine it back to being round. I should ofcorse have

realised this was going to happen but I didn't and

I was now facing making a new shaft - something I did

NOT look forward to. But then someone at a online forum

suggested to have the shaft plated to build up enough

material so it once again could be machined round and to

the right dimension and I got hold of a nice guy that

promised to help me with it.

And here it is. You can

see the newly applied metal at the top. I was kind of

expecting to see a nice shiny surface but this is what

it looked like. I chucked it up in the lathe and took a

light cut. The material was quite hard and left a nice

surface. I then brought the shaft back to the grinding

shop for a second time. As of today (2007-09-22) I

haven't got it back. We'll see how it works out.

Update 2007-09-29:

I got the spindleshaft

back from the grindingshop. They did a good job:

The shaft looks very nice.

The surface on the taper is a little rougher than on the

outside but still very nice. The dimensions are exactly

as I expected - no more, no less. I'm happy.

<BACK> <NEXT>

|