|

Mach3 has a built in macro/scripting

engine based on a product called Cypress ENABLE.

The scripting engine let's you edit the standard M-codes

but also enables you to create custom M-codes that can

be called from your G-code. A typical example is

modifying the M6 macros to operate an automatic toolchanger.

Another use of the

scripting engine is the button scripts. Behind some of

the buttons on the Mach3 screen there's a macro which is

run when you click that button (the RefAll button being

one of them). Those macros can be changed to work

different from what they do out-of-the-box. The RefAll

button for example can be changed so that the axis

home's in a different order or even all at the same

time. It's also quite easy to add your own buttons and

embedd macros in them to do custom things.

The macros can be created

and edited with any standard texteditor, like Notepad

for example, but

Mach3 has a built in editor with nice features like

syntax colouring, single stepping and breakpoints which

can be a big help when writing, testing and debugging

complex macros. The editor may not look "much" compared

to modern IDE's (Integrated Development Enviroment)

but it does what can be expected of it.

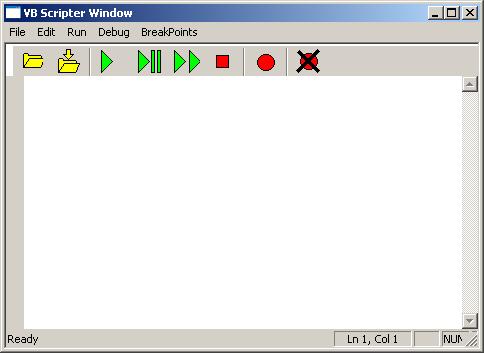

The editor is started by

selecting Operator/VB Script Editor and it

looks like this:

Besides all the commands

in the

CYPRESS ENABLE language Mach3 has a quite

a few commands that are callable from

the macros. These commands can be used to read values

from the various DRO's (GetDRO), check status of

Mach3's LED's (GetLED) and tell Mach3 to move the

machine to a certain position (Code "G0 X10")

among a lot of other things.

Let's say we want to create a button that "cycles" thru

the screens in Mach3. At our disposal we have a macrocall, GetPage(),

that returns an Integer stating which screen is displayed at the moment. All we

need to do is increment that number by one and then call

another command, DoOEMButton() that "pushes" the

correct screen select button for us. There are 50

screens available in Mach3 and by calling the command

DoOEMButton() with a number between 1 and 50 that

particular screen is displayed. The standard Mach3

screenset has only 6 screens so we write the code so

that only those first 6 screens will get displayed.

Dim Screen As Integer

'Declare a variable of type Integer

Screen = GetPage()

'Ask Mach3 which screen is being displayed now.

Screen = Screen + 1

'Increment that number...

If Screen > 6 then Screen = 1

'and make sure it stays between 1 and 6

DoOEMButton(Screen) 'Then display the next screen.

Suppose our spindle

motor has a springloaded break that needs to be

activated before we can turn the motor on. The relay for

the break is driven by Mach3's Output #3. When

the spindle is stopped the break should de-activate.

What we do is to modify the existing M3 and M5 macros

to look like this:

'---=== M3 Macro ===---

ActivateSignal(Output3) 'Release the break

Sleep (200)

'Wait

200mS

DoSpinCW()

'Start spindle

The

ActivateSignal(Output3) does just that - activates

Output #3 then we wait 200mS using the Sleep command to make sure that the

break has enough time to release. Finally we call

DoSpinCW() which actually starts the spindle. In

previous versions of Mach3 the Sleep command had to be

declared inside the VB-code but that is now handled by

Mach3 internally.

To turn the spindle OFF

and apply the break we modify the M5 macro to look

something like this:

'---=== M5 Macro ===---

DoSpinStop()

'Turn off the spindle

While GetOEMLED(813)

'Check the Dwell-LED and loop...

Sleep (50)

'here until it turns OFF

Wend

DeActivateSignal(Output3)

'Apply the break.

First we call DoSpinStop()

which is a Mach3 "command" to stop the spindle. In this

case the break is not supposed to actually break the

spindle but to hold it in place once it's stopped so it

wouldn't be a good idea to activate the break before the

spindle has come to a complete stop. To do that we can

look at Mach3's LED number 813. This is the Dwell

LED and it is ON while the spindle spins down. The

duration of the spin-down time is set in Mach3. Once the

Dwell LED goes off we call the command to turn off our

output. We use the sleep command here too but for

another reason. If we wouldn't have the sleep command

inside the While-Wend loop the scripting engine would

try it's best to check the LED as fast it possibly could

which would use up a lot of CPU power. By issuing a

sleep of 50mS the LED is only checked around 20 times

per second instead of tens of thousands.

Here's a macro that closes down Mach3 and

shuts down the PC. If saved as M300.m1s for example we

can call that instead of M30 at the end of the G-code

and it will shut down the PC for us.

Code "M30"

'Stop and rewind

If IsLoading = 0 Then

'Is

the code loading or should we actually run it?

Message("Shuting down...") 'Tell operator we are shutting down.

DoOEMButton(705)

'OEMButton705 shuts down the

PC

End If

When Mach3 loads a G-code program it runs

thru it to be able to create the toolpath display among

other things. This means that our macro code actually

gets executed which in this case would shut down the PC

as soon as the G-code program loads - not very good.

To prevent that from happening we can

call IsLoading(). It returns TRUE (or the

value 1) if the code executes due to it being loaded or

regenerated by Mach3. If the macro is run because the

G-code is actually being executed IsLoading()

returns FALSE (or the value 0). If the G-code is

executing we "push" OEMButton 705 which shuts down Mach3

and the PC.

Genrally it's not recomended to call one

macro from another like is being done here but it this

case it seems to work just fine.

Basically anything you can do in G-code can

be done from a macro by sending G-code statements to

Mach3 with the Code-command. Here's a (very simple)

example:

Dim i As Integer

'Declare a variable, i, of type

integer

Code "G91"

'Switch to INC mode.

For i = 1 To 5

'Loop 5 times

Code "G0 X5"

'Move the X-axis 5 units

Code "G0 Y5"

'Move the Y-axis 5 units

Next

Code "G90" 'Switch back to ABS mode.

We can also use the

scripting engine to create G-code for us. By

calling the command OpenTeachFile() all Code-statements

from now on will be written to that file instead of

being executed by Mach3. We can then ask Mach3 to load

the previously created file by calling LoadTeachFile().

The following example shows how that can be used. It

displays a series of dialog boxes asking the user to

enter information and "writes" the code based on the

data entered. The code can easily be extended with

features like error-handling (user enters non numeric

data, for example).

Dim Xpos, YPos, SpindleSpeed, Feed, Depth As Double

Dim Clearance, Peck, Dwell As Double

Dim i, Holes As Integer

OpenTeachFile "G83 Drill.tap"

'Open

the teachfile, name G83 Drill.tap

SpindleSpeed = InputBox("Please enter desired spindle speed:")

'Ask

user to input spindle speed

Feed = InputBox("Please enter desired feedrate:")

'Ask user to input feedrate

Code "M3 S" & SpindleSpeed & " F" & Feed

'Write

G-code to file.

Holes = InputBox("How many holes to drill?")

'Ask

user how many holes to drill

If Holes > 0 Then

Depth = InputBox("How deep are they?")

Peck = InputBox("How deep per peck?")

Clearance = InputBox("Please enter the Z axis clearance

height between holes")

Dwell = InputBox("Please enter dwell time in seconds")

Xpos = InputBox("X coordinate for hole no. " & 1 & "?")

Ypos = InputBox("Y coordinate for hole no. " & 1 & "?")

Code "G83 X" & XPos & " Y" & YPos & " Z-" & Depth & " R" &

Clearance & " P" & Dwell & " Q" & Peck

For i = 2 To Holes

Xpos = InputBox("X coordinate for hole no. " & i)

Ypos = InputBox("Y coordinate for hole no. " & i)

Code "X" & Xpos & " Y" & YPos

Next

Code "G80"

End If

LoadTeachFile()

CloseTeachFile()

This example creates a

file called myFile.txt in the Mach3 folder. It

then reads the current position of the X-axis and writes

it to the file. Lastly it closes the file.

Dim X as Double

Open "C:\Mach3\myFile.txt" For Output As #1

X = GetDRO(0)

Print #1, X

Close #1

And here's code that opens the file created

in the previous example and reads a single line from it.

It then asks the user if it's OK to move the X-axis to

the position stored in the file.

Dim Answer

Dim newPos As Double

Open "C:\Mach3\myFile.txt" For Input As #2 'Open the file for reading

Line Input #2, newPos

'Read the first line of the file

Answer = MsgBox ("Is it OK to move the X axis to: " &

newPos & "?", 1)

If Answer = 1 Then

'You pressed OK

Code "G0 X"& newPos 'Make the move

End If

Close #2

'Close the file

This snippet of code

simply takes the content of the tool table in Mach3 and

saves it to a .txt file. The will be saved in the Mach3

directory as myTools.txt but that can obviously be

changed whatever is needed.

Option Explicit

Dim Response As Integer

Dim Path As String

Dim ToolNumber As Integer

Dim ToolDiameter As Double

Dim ToolLength As Double

Dim ToolDescription As String

Dim i As Integer

Path = GetMainFolder & "myTools.txt"

Open Path For Output As #1

Print #1, "Mach3 Tooltable printout" & Date() & " " &

Time(Now)

Print #1,""

Print #1, "Tool:" & Chr(9) & "Diam:" & Chr(9) & "Length:"

& Chr(9) & "Description:"

For ToolNumber = 1 To 250

ToolDiameter = GetToolParam(ToolNumber, 1)

ToolLength = GetToolParam(ToolNumber, 2)

ToolDescription = GetToolDesc(ToolNumber)

Print #1, ToolNumber & Chr(9) & ToolDiameter & Chr(9) & ToolLength

& Chr(9) & ToolDescription

Next

Response = MsgBox("Your file is at the following

location: " & Path, 0)

Close #1

On the Mach3 Yahoo user

group a user asked if it was possible to change the

acceleration of an axis from a G-code program. The idea

behind the question to create a program which kept

increasing the acceleration while running the axis back

and forth in order to find a suitable value. I usually

just do it thru trial and error but I kind of liked the

idea so I came up with the following code.

(This has actually been

expanded a bit from what I originally posted).

Option Explicit

Dim CurrAcc As Double

Dim AccIncrease As Double

Dim Axis As Integer

If IsLoading() <> 1 Then

Axis = Param1() ' Get P-value in call

AccIncrease = Param2() ' Get Q-value in call.

Select Case Axis

Case 0 'X-axis

CurrAcc = GetParam("AccelerationX") ' Get current acceleation.

SetParam("AccelerationX", CurrAcc + AccIncrease) ' Set new

acceleration.

Case 1 'Y-axis

CurrAcc = GetParam("AccelerationY") ' Get current acceleation.

SetParam("AccelerationY", CurrAcc + AccIncrease) ' Set new

acceleration.

Case 2 'Z-axis

CurrAcc = GetParam("AccelerationZ") ' Get current acceleation.

SetParam("AccelerationZ", CurrAcc + AccIncrease) ' Set new

acceleration.

Case 3 'A-axis

CurrAcc = GetParam("AccelerationA") ' Get current acceleation.

SetParam("AccelerationA", CurrAcc + AccIncrease) ' Set new

acceleration.

Case 4 'B-axis

CurrAcc = GetParam("AccelerationB") ' Get current acceleation.

SetParam("AccelerationB", CurrAcc + AccIncrease) ' Set new

acceleration.

Case 5 'C-axis

CurrAcc = GetParam("AccelerationC") ' Get current acceleation.

SetParam("AccelerationC", CurrAcc + AccIncrease) ' Set new

acceleration.

End Select

End If

If the above is saved as,

for example, M1234.m1s it can be called from a G-code

program. So if we wanted to run the Y-axis back and

forth, increasing the acceleration by 25 units/s/s each

time the G-code program could look something like this:

G0

Y100

G0 Y0

M1234 P1 Q25

M47

|